Owners of bulk materials handling sites and terminals buy grain from growers in their country, and then ship or export it as it is sold. Bulk handling sites must manage fluctuating needs throughout the agriculture supply chain, depending on when different agriculture products, such as wheat, barley, beans, and canola, are harvested in that country. These sites require lots of infrastructure and real estate to run operations, and require many people to keep these facilities running.

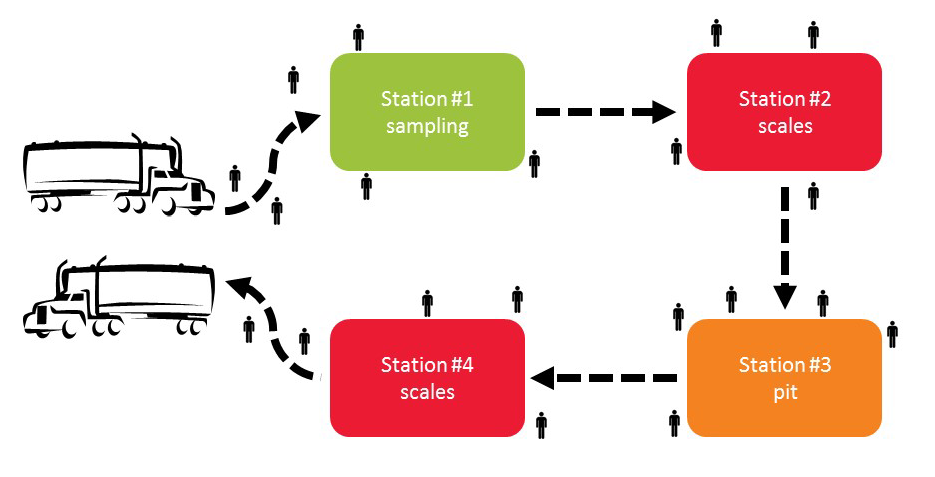

The receival process at a bulk handling site typically looks something like this:

- Trucks arrive at the site to deliver agricultural products from the growers.

- At Station #1, site workers take a sample of the product from the truck and test it to determine which type of commodity it is (for example, wheat, barley, beans, or canola) and its quality level [for example, HW1 (hard wheat 1) or HW2 (hard wheat 2)].

- The truck continues to Station #2 where the truck and its cargo are weighed (for example, 50 tonnes). With the combined information of quality and weight, the operator can now determine where this truck should deliver its cargo, and the truck driver is instructed to where he should proceed (Station #3).

- Once at the location (Station #3), the truck delivers its cargo to a specific pit, grid, or silo.

- The truck continues to Station #4 where it is weighed again (for example, 30 tonnes) and by subtracting this weight from the original weight measured at Station #2, the operator knows the total quantity of what was delivered (20 tonnes).

- The driver is given a receipt for what he delivered, and the truck exits the site.

Without automation, the receival process is typically very manual and labor intensive.

The top three challenges for today's agricultural bulk handling sites are:

1) Long Queue Times

Agri-commodities are delivered to the bulk handling site, typically by truck or train. As growers’ trucks visit sites to deliver product, delays in the receival process can adversely affect the profits of the site operator, as can equipment failures at the site.

In some countries, the flow of product through bulk handling sites increases greatly during peak harvest seasons, and in other countries, the flow of product is more consistent throughout the year. Sites that have long lines in which trucks must wait to enter the site will lose business to other sites that operate more efficiently.

Long queue times can add other costs and risks for site operators. With long lines of trucks at the site, it may not be a safe environment for idle truck drivers. Depending on the country, long queue times can result in costly fines for site operators.

2) The Need for Temporary Workers

During peak harvest times, sites frequently hire additional workers for 3-4 months. These temporary workers may be inexperienced, which can cause training and safety issues. In addition to the challenge of added costs, sites that hire temporary workers each year are exposing themselves to risk. This risk can be minimized or eliminated if sites can lessen their need for seasonal workers.

3) Growing Production Needs

It is inevitable that globally, production needs will rise for agri-commodities as world population increases. Therefore, bulk handling sites will need to manage more agri-commodities in the future, and to do that, they will need to increase efficiency.

Bulk handling sites that operate less efficiently than others in their geographic area will lose business. Site operators need to find ways to become more automated and reduce costs.

Automation

As agricultural production increases due to growing global population, bulk handling sites will need to look for ways to reduce costs and increase throughput with agriculture supply chain software. The smart bulk handling site of the future will leverage automation as a way of increasing efficiency. Specific tools that will be implemented include:

- Automated truck scales or weighbridges

- Control software to operate everything at a site or a network of sites

- Automated sampling probes

Eka's InSight CM platform provides bulk stock management, process management, task execution, and business intelligence for the bulk handling industry including grain facilities and port terminals for all types of commodities. With Eka’s bulk handling software platform, physical assets (machinery, storage locations, ports, etc.) operate at maximum efficiency in the storage or movement of physical bulk commodities — providing the most throughput for the least amount of downtime and cost.